PEM Water Electrolysis Component Coating Manufacturers

Green hydrogen is widely accepted as a critical part of advancing the energy transition. However for it to become a reality the technology used to generate it, such as PEM Electrolysers, must demonstrate both performance and affordability. TFP Hydrogen’s specialised coatings play an important role in enabling this; they enhance the performance, efficiency and durability of PEM electrolysers to effectively reduce the lifetime cost of green hydrogen production.

WHAT IS WATER ELECTROLYSIS & WHY IS IT IMPORTANT?

Hydrogen is a rapidly expanding market driven by support from global policy and targets. However, to make the mainstream use of hydrogen a reality, the

technologies used to generate it must demonstrate both performance and affordability. Water electrolysis is one of these technologies.

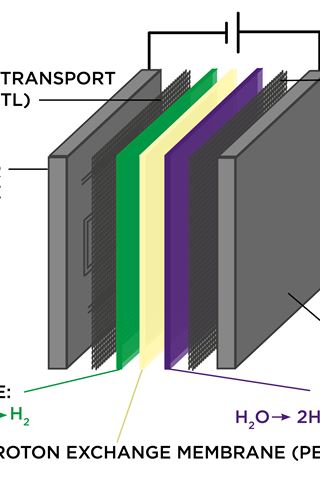

An electrolyser is an electrochemical device used to convert electricity and water into hydrogen and oxygen, providing a means to store the energy for later use. PEM water electrolysers can be used both to store energy from wind turbines and solar cell (generating ‘green hydrogen’), or in localised hydrogen production to power hydrogen fuelled vehicles. The technology enables the management of high current densities from dynamic energy sources (such as wind energy), as well as generating hydrogen with the high purity necessary for use in fuel cells.

To be competitive PEM electrolysers must operate at high energy efficiencies (80%+) for long time periods, a target that TFP Hydrogen Products’ coatings can enable them to meet.

COATINGS TO INCREASE ELECTROLYSER EFFICIENCY & LIFETIME

We are experts in the development of electrochemical materials and our specialist coatings can reduce the cost of green hydrogen production using PEM water electrolysers by increasing both stack efficiency and lifetime.

We offer a range of coatings designed specifically for PEM electrolyser components which both reduce and stabilise the internal resistances that (if not maintained at a low level) would lead to increased energy consumption over the systems operational lifetime.

Our coatings are used on a number of different titanium PEM electrolyser components to increase the performance and lifetime of the system. The coatings protect Cell Separators, Bipolar and Unipolar plates from corrosion, reducing hydriding & embrittlement which increases the ohmic resistance and can lead to mechanical failure. The result is improved long term component performance and cell lifetime.

The coatings offer the same corrosion protection benefits for macro transport layer meshes and porous transport layers (PTLs), such as titanium sinters & felts, as well as being designed to lower the interfacial contact resistances of these components and maintain this over 10,000s of hours. In PTLs the specially designed coatings also protect against oxidation and reduce overpotential, enabling operation at high energy efficiency over long time periods. All these benefits mean that the electrolyser system is able to operate at high energy efficiency over long time periods, which is necessary to make green hydrogen production more competitive.

TFP Hydrogen offers a range of capabilities as a supplier, with off-the-shelf formulations and a rapidly scalable coating process which enables the capacity to mass produce products. We have a highly experienced team of specialists in chemistry, electrochemistry, electrochemical engineering, materials science and analytical science who can specify the optimum coating formulation for your application. We welcome the opportunity to collaborate with our customers to develop coatings to suit their needs, whether this be in terms of durability, cost or efficiency.

SOLUTIONS FOR PEM ELECTROLYSERS

THE KEY BENEFITS:

- High quality coatings enable operation at high energy efficiencies and increase component durability.

- Coated metal stack components have a low contact resistance which is maintained over 10,000s of hours.

- Coatings can be applied to a range of components including foils, porous media, plates and meshes.

- Our coatings also provide corrosion protection, minimising maintenance.

- Specialist coatings have an inherent ability to withstand oxidation and hydriding.

- Very competitive on price due to unique coating method.

- Coatings can be tailored to suit the system requirements.

- A development can be taken from laboratory concept to industrial scale manufacture. Our process is fully scalable to meet customer demand.

Ultimately, the key benefit to using TFP Hydrogen Products’ coating on components is a reduced cost of green hydrogen production over the operational lifetime of the PEM water electrolyser stack.

Would you like more information?

Please get in touch, we'd love to hear from you.